February 15, 2025 – TPE Products Face Frosting Challenge: Causes and Prevention

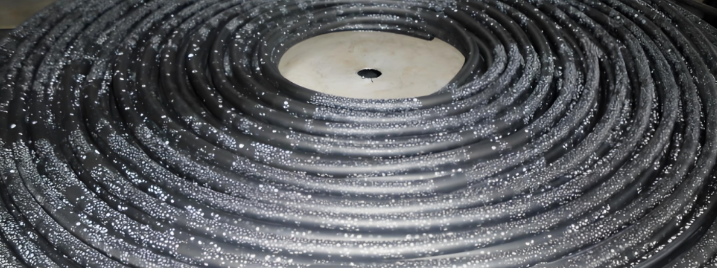

TPE (thermoplastic elastomer) product manufacturers have long been troubled by the issue of surface frosting. This phenomenon, characterized by a layer of white powdery or frosty substance on the material’s surface, is primarily caused by the migration and crystallization of internal components. So, what factors contribute to this occurrence?

From the perspective of TPE formulation, improper selection or ratio of antioxidants, or poor dispersion during processing, can lead to antioxidant exudation. Additionally, while lubricants enhance processing performance, excessive use can result in their precipitation on the product surface, causing frosting. Furthermore, excessive fillers or inadequate surface treatment, as well as excessive oil content, can cause oils or fillers to migrate to the surface, forming deposits. Particularly, small molecules such as plasticizers and internal release agents, if improperly chosen or overused, can migrate over time to the TPE surface, inducing frosting.

According to Color Masterbatch Industry Network, processing and storage conditions also play a significant role in TPE surface frosting. Excessively high or low processing temperatures can affect material stability, leading to component precipitation on the surface. Prolonged residence time in processing equipment may cause thermal degradation or chemical changes, resulting in surface deposits. Moreover, the use of release agents requires caution; excessive or uneven application can lead to localized whitening or frosting. During storage, environmental factors like light, UV rays, and temperature can accelerate component migration and precipitation.

So, how can we prevent this precipitation phenomenon from the TPE formulation standpoint? Firstly, collect the precipitated substance and use methods such as combustion analysis and infrared spectroscopy to determine its chemical composition, thereby identifying the source. Secondly, control the usage of additives like internal and external lubricants, and antioxidants, to avoid small molecule exudation. Additionally, manage the type and amount of fillers, and pre-treat incompatible fillers. Lastly, control the oil content based on TPE material characteristics, ensuring moderate oil levels in SEBS, SBS, and other materials to prevent oil exudation.