April 8, 2025 – On April 3, Times New Material Technology Co., Ltd. (Stock Code: 600458) released an announcement. In the first quarter of 2025, the company successfully signed a “Blade Sales Contract” with leading wind turbine manufacturers in the wind power industry. The total contract value reached a staggering 1.98 billion yuan (including tax), with 210 million yuan attributed to offshore wind power projects. The signing of this large – scale order not only further solidifies Times New Material’s position in the wind turbine blade market but also lays a solid foundation for its annual performance growth.

Looking back at 2024, Times New Material achieved remarkable results and presented an impressive report card. The company’s operating income successfully surpassed the 20 – billion – yuan mark, showing a year – on – year growth of 14.35%. Among the segmented sectors, the wind turbine blade sector witnessed a rapid growth in revenue, with an increase of 22.37%, and the rail transit sector also performed outstandingly, with a growth rate of 25.60%. In terms of net profit, it reached 445 million yuan, a year – on – year increase of 15.20%. Notably, its overseas subsidiary, Sinomatech Germany (Boge), successfully turned losses into profits. Driven by the coordinated efforts of core business sectors such as wind power, rail transit, and automotive parts, Times New Material is in a favorable development trend. Especially in the wind power field, with the continuous acceleration of the global energy transition process, the demand for wind turbine blades has been on the rise. Times New Material has outperformed in the market competition with its own excellent technical advantages.

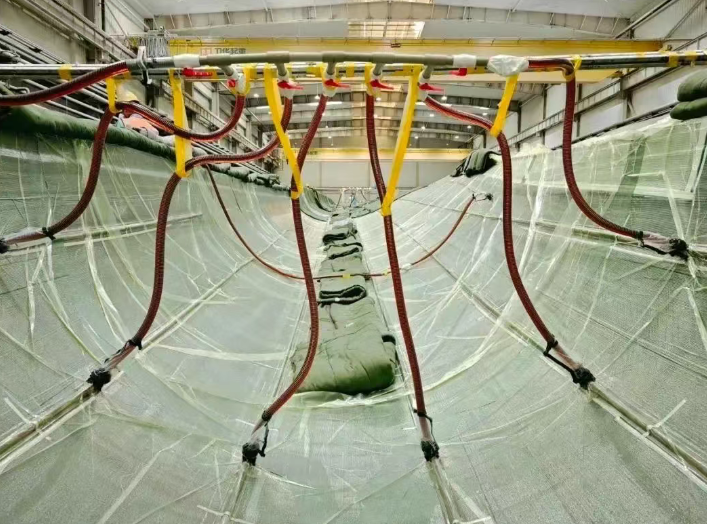

According to AsiaMB, against the backdrop of the “dual – carbon” goal, the recycling of wind turbine blades has always been a thorny issue in the industry. Traditional thermosetting resin blades are non – biodegradable, and after decommissioning, most of them can only be disposed of by landfilling or incineration. This not only causes a large amount of resource waste but also pollutes the environment. However, Times New Material recently achieved a major technological breakthrough. Its independently developed domestic first – set of recyclable thermosetting resin blades, TMT82, was officially shipped from the factory in Sheyang, Jiangsu. This achievement marks a substantial leap in China’s wind turbine blade recycling technology. The TMT82 blade features an extra – long design of 82 meters, and its swept area is equivalent to the size of three standard football fields. This design has been optimized for large – scale wind turbines. In terms of technical principles, this blade uses reversible chemical bond technology, which can efficiently separate the resin from the glass fiber through directional depolymerization. The recycled materials after separation can be re – applied to the production of new blades or other composite materials, truly achieving a win – win situation for the environment and the economy. It has successfully broken the dilemma of traditional blades being “waste as soon as they are decommissioned” and significantly reduced the carbon footprint throughout the life cycle. Chen Huang, the deputy director of the Wind Power Development Center of Times New Material, said: “The installation application of TMT82 fills the domestic gap in this area and provides a replicable green solution for the industry.”

The Global Wind Energy Council (GWEC) predicts that by 2030, the weight of decommissioned wind turbine blades in China will exceed 30,000 tons. Times New Material’s recyclable technology has explored three feasible paths for the entire industry. In terms of material innovation, it vigorously promotes the reversible resin system, effectively reducing recycling costs; at the policy – driven level, the European Union has put forward a requirement of 85% for the recyclable proportion of blade materials, and domestic relevant standards are expected to follow suit gradually; in terms of industrial chain collaboration, it cooperates with wind turbine manufacturers and recycling enterprises to jointly build a closed – loop ecosystem.

From the signing of the 1.98 – billion – yuan large – scale order to the successful implementation of the recyclable blade technology, Times New Material fully demonstrates the powerful ability of “market + innovation” dual – wheel drive. In the field of renewable resources, the recycling of wind turbine blades has just started, but the technological breakthrough has already brought new opportunities for the industry’s development. In the future, how to achieve large – scale promotion and further reduce costs will become problems that enterprises and the entire industrial chain need to overcome together.