December 2, 2024 – A new material called Calcium Carbonate Filled Masterbatch has recently garnered significant attention in the plastics industry. This masterbatch, crafted through a blend of calcium carbonate and a PP carrier, is tailored for the production of various polyethylene products, spanning injection molding, piping, blow molding, sheeting, vacuum forming, woven bags, colored strip fabrics, PE cloths, plastic nets, film blowing, and cast films. Its unique attributes have caught the eye of numerous manufacturers.

One of the standout features of the Calcium Carbonate Filled Masterbatch is its ability to notably reduce production costs and enhance efficiency, thereby bolstering the economic gains for businesses. Moreover, it reinforces the rigidity of the products, increases their weight, minimizes shrinkage and resultant deformation, and ensures consistent product quality. Impressively, this masterbatch boasts excellent dispersion and superior compatibility with polypropylene and polyethylene. Even with substantial filler content, it maintains the aesthetic appeal of the products, meeting customers’ high standards for visual appeal.

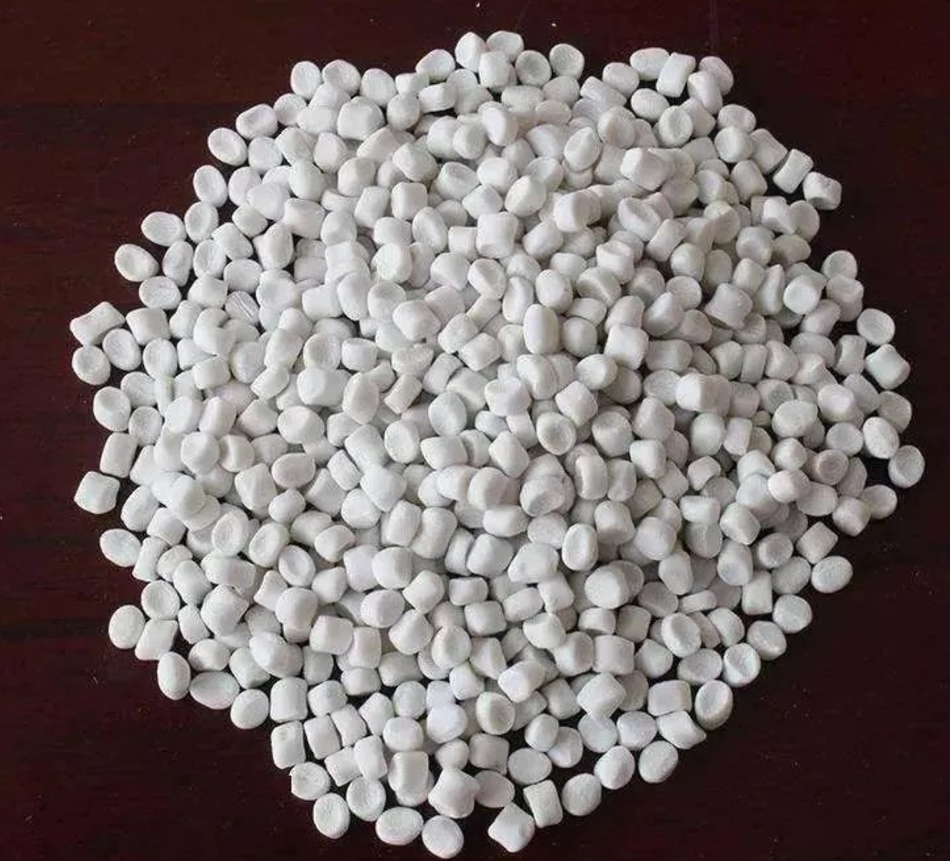

According to AsiaMB’s sources, the masterbatch also stands out for its high whiteness, presenting as pure white pellets that can be flexibly formulated to produce a spectrum of colored products, thereby expanding the possibilities for product diversification. Furthermore, thanks to coupling agent treatment, the products retain excellent mechanical properties even with significant filler content. The masterbatch also offers broad processing adaptability, allowing customers to integrate it into their existing equipment and production processes without any hassle. Notably, it includes antioxidants and anti-aging agents, effectively prolonging the lifespan of the products.

In terms of composition, the Calcium Carbonate Filled Masterbatch predominantly consists of 1500-mesh calcium carbonate, virgin PP pellets, along with coupling agents, antioxidants, anti-aging agents, and other additives. Specifically, the 1500-mesh calcium carbonate accounts for 70%, virgin PP pellets make up 20%, and the additives comprise 10%. This formulation ensures both the stable performance of the masterbatch and its reliability during application.

However, when utilizing the Calcium Carbonate Filled Masterbatch, certain precautions should be taken. It is essential to protect the masterbatch from moisture and direct sunlight during transportation, storage, and usage to maintain its quality. As the adoption and application of this masterbatch continue to grow, it is poised to bring about more innovations and transformations in the plastics industry.