May 7, 2025 – On April 29, 2025, KBR, a globally renowned engineering and construction firm, announced its full support for Samsara Eco, a biotechnology innovator, in designing its first enzyme-based plastic and textile recycling plant. The plant is expected to be completed and commence operation in early 2028.

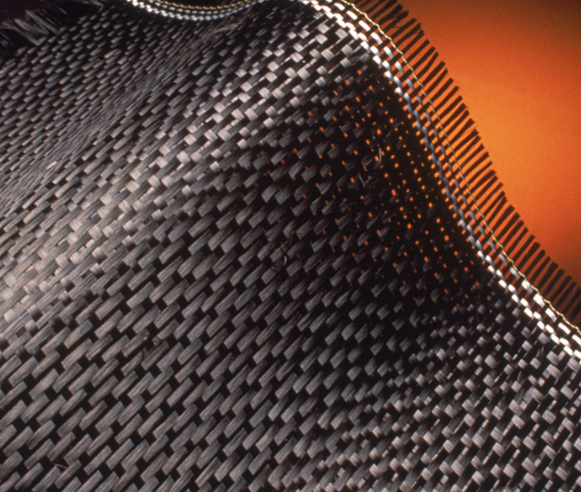

Samsara Eco, an innovative enterprise dedicated to sustainability, has developed groundbreaking enzyme-based recycling technology in the field of plastic and synthetic fiber recycling. Currently, due to the complex chemical structures and material properties of some common plastics and synthetic fibers, traditional recycling methods often struggle to recycle them effectively, or are even unable to do so at all. Samsara Eco’s technology aims to overcome this hurdle by establishing a continuous recycling loop. With the aid of its proprietary artificial intelligence platform, the company’s patented enzymes can precisely break down plastics into their original monomer components. This process not only enables the continuous remanufacturing of plastics into new products without quality degradation but also has the advantage of being low-carbon and environmentally friendly. Compared with other recycling methods, Samsara Eco’s enzyme-based recycling technology has proven effective in recycling extremely challenging plastics like nylon 6,6, as well as mixed fibers, and colored and dyed blended fabrics. According to AsiaMB, this breakthrough technology is crucial for achieving the ambitious goal of recycling all plastics, and it is expected to help numerous companies utilize resources more efficiently, transforming what was once landfill waste into valuable reusable resources.

Under the terms of the agreement reached between the two parties, KBR and Samsara Eco will jointly complete the pre-FEED (front-end engineering design) work for the project by the end of the second quarter of 2025. Subsequently, KBR’s technical experts and business elites will provide the FEED engineering package for the process design, facilitating the construction of a commercial production facility with an annual output of 20,000 tons of nylon 6,6.

Jay Ibrahim, President of KBR’s Sustainable Technology Solutions, stated, “KBR has a unique edge in offering world-class solutions to assist clients in successfully bringing sustainable technologies to market. We are honored to support Samsara Eco in this highly distinctive project. This contract further reinforces our unwavering commitment to sustainability and technological innovation.”

Paul Riley, Founder and CEO of Samsara Eco, also commented, “We are fully committed to advancing the construction of our first plant, aiming to drive the circular economy and help our brand partners realize their vision of creating more circular products using low-carbon recycled materials. KBR’s unparalleled engineering expertise will ensure that we can design and build the plant quickly and accurately. We are extremely honored to have KBR’s support in scaling up our technology to an industrial level.”

In fact, Samsara Eco has already partnered with many leading brands, including lululemon, to replace virgin materials with recycled ones. Last year, Samsara Eco successfully launched the world’s first enzyme-recycled nylon 6,6 product, followed by the first product made from enzyme-recycled polyester fibers – the lululemon limited-edition Packable Anorak jacket. This collaboration with KBR is expected to further accelerate the industrial application of Samsara Eco’s enzyme-based recycling technology, bringing about a new revolution in the global plastic and textile recycling field.