July 20, 2025 –

Japan Opens Doors to Next-Gen Bioplastics in Food Packaging Revolution

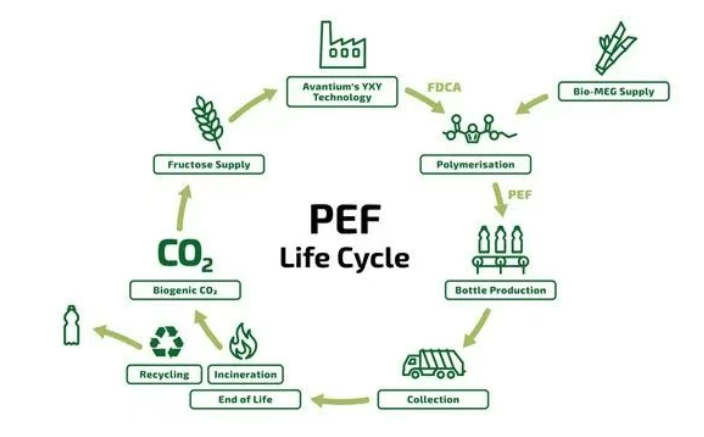

Japan’s food contact material regulations have entered a new era with the inclusion of 2,5-Furandicarboxylic Acid (FDCA) in its Positive List system, effective June 2025. This landmark decision clears regulatory hurdles for polyethylene furanoate (PEF), a plant-based polymer poised to transform sustainable packaging across Asia.

The Ministry of Health, Labour and Welfare’s approval specifically authorizes FDCA-derived materials for food contact applications, validating PEF’s safety credentials after extensive evaluation. Industry observers note this creates immediate opportunities for bio-based alternatives in Japan’s $3.2 billion food packaging market, particularly for oxygen-sensitive products like juices and ready meals.

Dutch chemical firm Avantium, holding key patents for PEF production through its YXY® technology platform, confirmed accelerated plans for Asian market entry. “Japan’s rigorous approval process sets a gold standard for bioplastics adoption,” said Avantium’s Asia-Pacific director Mark Velders. The company’s pilot plant in Delfzijl currently produces 5,000 tons annually, with commercial-scale facilities under development.

Technical assessments reveal PEF’s exceptional properties:

• 10x superior oxygen barrier versus conventional PET

• 55-70% lower carbon footprint across lifecycle

• Full compatibility with existing mechanical recycling streams

• Enhanced thermal stability for hot-fill applications

The regulatory breakthrough comes as Japan implements stricter migration limits for food contact substances under its updated Food Sanitation Act. FDCA’s inclusion follows a comprehensive safety dossier submission demonstrating compliance with Japan’s 0.05mg/kg daily intake threshold for new monomers.

Market analysts project PEF could capture 15-20% of Japan’s premium beverage packaging segment within three years, driven by brand owners’ sustainability commitments. Kirin Holdings recently completed successful trials of PEF-based beer bottles, citing 30% longer shelf life without taste alteration.

For color masterbatch specialists, the development presents both formulation challenges and opportunities. PEF’s higher processing temperatures (260-280°C) demand heat-stable pigment systems, while its amber tint may reduce colorant loads for certain applications. AsiaMB will monitor how these technical requirements reshape additive development across the region.