October 23, 2024 – Global Engineering Plastics Leader Polyplastics Unveils Sustainable Innovation with LAPEROS® bG-LCP

Polyplastics Co., Ltd., a leading player in the engineering plastics industry, has recently announced a significant breakthrough with the introduction of LAPEROS® bG-LCP. This latest addition to their product portfolio is a sustainable solution crafted from biomass-derived materials using the mass balance method. It aims to reduce carbon dioxide emissions and increase the proportion of renewable components, thereby advancing the development of eco-friendly materials.

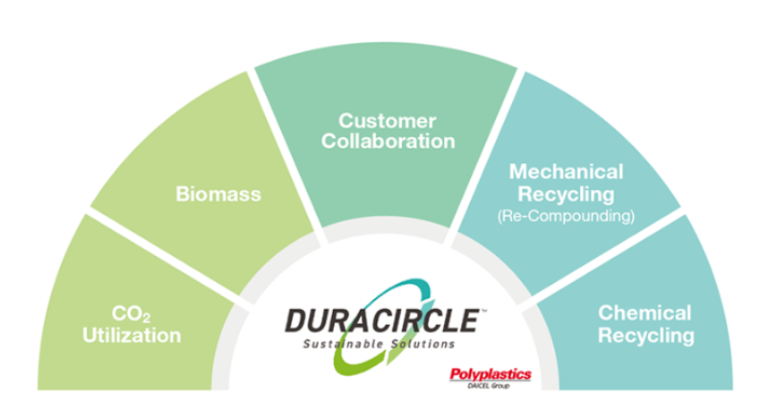

With the launch of LAPEROS® bG-LCP, Polyplastics further enriches its DURACIRCLE® program, which already includes DURACON® Toughgrade® bG-POM. The new product is expected to be commercialized in the spring of 2025, featuring the same production process and identical chemical and physical properties as Polyplastics’ traditional offerings. The company plans to gradually extend this innovative solution across its entire range of LAPEROS® LCP products.

According to Color Masterbatch Industry News, the mass balance method is an innovative production approach that combines raw materials derived from biomass with those extracted from fossil resources. Depending on the input ratio of biomass raw materials, these materials are skillfully integrated into the resin production process, making a portion of the final product biomass-derived. This method not only simplifies the production workflow but also avoids the complexity of separately producing biomass-derived and fossil-derived products.

LAPEROS® LCP is renowned for its thin-wall capabilities, high flowability, excellent heat resistance, and robust mechanical properties. Even when the thickness is reduced, it maintains high strength per unit area and has a low coefficient of linear thermal expansion close to that of metals. As a result, LAPEROS® LCP is widely used in ultra-small precision connectors and other components for cutting-edge IT devices such as tablets and smartphones.

Polyplastics’ DURACIRCLE® program is dedicated to generating higher-performance and more valuable materials by utilizing renewable raw materials, resin recycling, and re-compounding processes. The program encompasses various initiatives, including biomass-balanced products like LAPEROS® bG-LCP and DURACON® Toughgrade® bG-POM, expanding the use of post-consumer recycled (PCR) sources, chemical recycling, and developing raw material technologies for carbon dioxide capture and reuse. Through these efforts, Polyplastics is actively driving the sustainable development of the chemical industry and the realization of a circular economy.