October 27, 2024 – Navigating the world of packaging materials can often feel like a daunting task, especially when faced with popular options like PET (polyethylene terephthalate) and PVC (polyvinyl chloride). Each material boasts its unique set of advantages and disadvantages, making the decision-making process all the more crucial. This article delves into the intricacies of these two plastics, aiming to assist you in making an informed choice.

PET packaging has garnered significant attention in recent years, primarily due to its impressive recycling rates. By 2018, the recycling rate for PET bottles and packaging had reached 29.1%, marking a substantial step towards circular economy efforts. So, what makes PET a standout in the packaging industry? Composed of terephthalic acid and ethylene glycol, PET is a sturdy, transparent, and lightweight non-glass plastic that also exhibits antimicrobial properties. These characteristics make it a favorite for thermoformed packaging designs, including food and beverage containers, where its durability shines even under prolonged exposure to moisture and air.

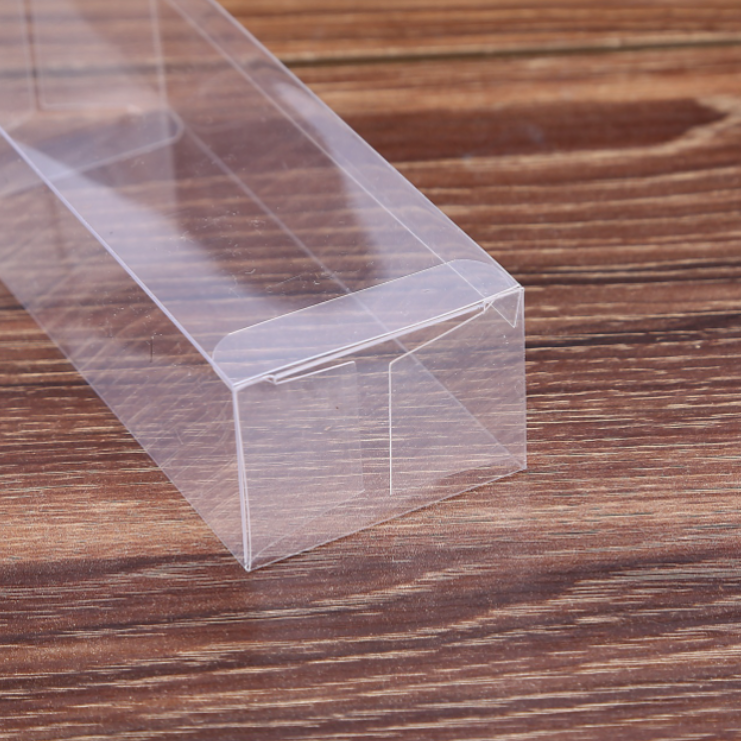

The merits of PET packaging, as echoed by the Color Masterbatch Industry Network, are numerous. Its excellent recyclability contributes to reducing plastic waste and promoting environmental sustainability. PET’s lightweight nature, particularly in non-woven bags, minimizes transportation costs and energy consumption. Furthermore, its durability makes it ideal for protecting fragile products such as drinks, vegetables, and fruits. The transparency of PET allows consumers to see the product clearly, a significant advantage in food and beverage packaging. However, PET is not without its drawbacks, including environmental impact, UV sensitivity, and limited temperature resistance.

On the other hand, PVC packaging presents a different set of attributes and challenges. PVC is a versatile plastic used in various applications from packaging to construction materials. However, concerns regarding its environmental and health risks during production and disposal persist. While PVC offers cost-effectiveness, durability, and widespread use, these benefits are overshadowed by the potential hazards it poses. The production and disposal of PVC can emit hydrochloric acid, harming both the environment and human health. Furthermore, additives like plasticizers in PVC can leach into food and beverages, posing potential health risks.

So, how do PET and PVC plastics differ? From an environmental and health perspective, PET is generally considered the greener option. It is more easily recycled and has a lower overall environmental footprint. In contrast, PVC’s production and disposal generate more harmful pollutants and present greater health risks. Functionally, PET’s lightness and transparency make it ideal for food and beverage packaging, while PVC’s enhanced durability and heat resistance suit applications requiring rigidity and strength.

When comparing PET and PVC packaging, the choice ultimately hinges on your product’s specific needs, costs, and environmental considerations. While PVC may offer cost-effectiveness and durability, PET leads the way in environmental performance. For businesses prioritizing sustainability, PET is undoubtedly the preferred choice. However, if strength and cost are paramount, PVC may still be a viable option. In the broader scheme of sustainable packaging, PET holds a distinct advantage.