January 4, 2025 – PE Road Mats: The Innovative Solution for Wind Power Project Challenges

Polyethylene (PE) road mats, crafted from high-molecular-weight polyethylene through advanced high-temperature extrusion processes, have emerged as a game-changer in the wind power industry. These thermoplastic engineering plastic mats combine lightweight design, corrosion resistance, wear durability, slip prevention, high load-bearing capacity, and easy installation and maintenance, making them the top choice for project construction in the wind energy sector.

Wind power projects often find themselves in remote and topographically complex locations, from vast grasslands to rugged mountains, muddy wetlands, and soft sandy terrains, posing unprecedented challenges for the transportation, installation, and maintenance of wind turbines and equipment. The advent of PE road mats has bridged these gaps, providing a solid and reliable pathway for the smooth progression of wind power projects.

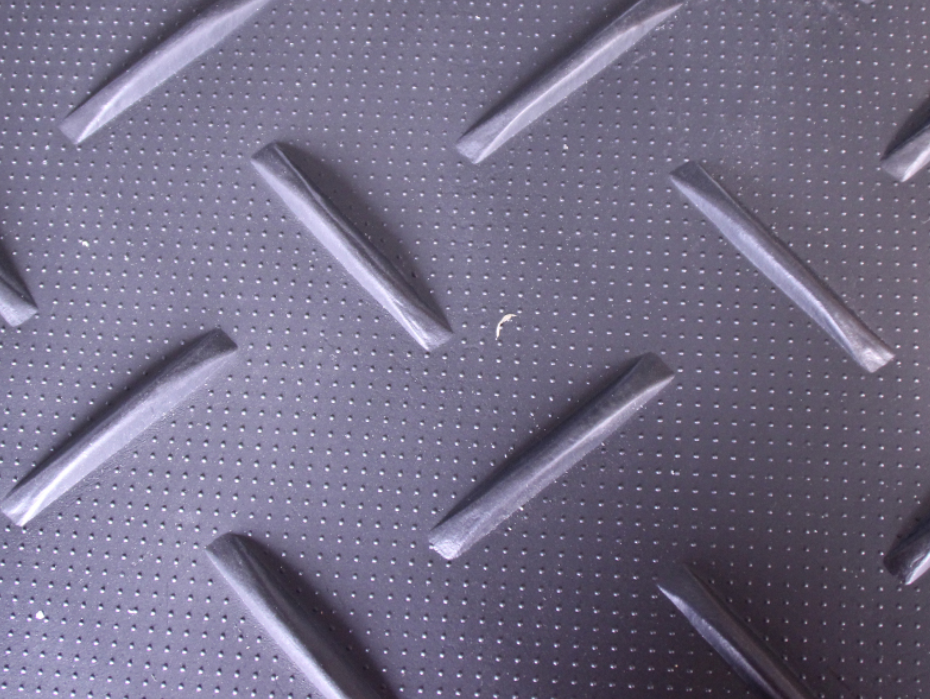

According to the Color Masterbatch Industry Network, during the transportation of large equipment such as wind turbine towers and blades, PE road mats excel with their exceptional load-bearing capacity and anti-slip design. They effectively distribute vehicle weight, protecting fragile ecosystems from damage. The unique anti-slip patterns on the surface ensure stable vehicle movement even in wet and slippery conditions, enabling rapid traversal of complex terrains. These mats also significantly reduce the risk of vehicles getting stuck in mud, avoiding transport delays and equipment damage caused by terrain factors.

During the installation phase at wind farms, PE road mats play a pivotal role. They are easy to assemble and can be flexibly adjusted in size according to on-site requirements, quickly establishing temporary roads to wind turbine units. This greatly shortens the construction period and reduces costs. For lifting equipment and construction personnel, PE road mats provide a stable working platform, ensuring construction safety and efficiency.

The widespread application of PE road mats in wind power projects is attributed to their outstanding performance. Polyethylene material exhibits excellent chemical resistance, withstanding the corrosion of various acids, alkalis, and salts. It also maintains stable operation within an extreme temperature range of -70°C to +80°C, significantly broadening its usage scope. Furthermore, PE road mats possess high compressive strength, capable of withstanding the pressure of heavy vehicles. Their lightweight nature facilitates easy handling and installation, while specially treated mats effectively resist UV exposure, extending their service life.