October 14, 2024 – The transparent polypropylene industry in China has been thriving in recent years, with robust growth observed in both production and sales. This upward trend can be attributed to the continuous introduction of new processes and varieties, which have significantly expanded production scale, efficiency, product diversity, and application fields. As a result, transparent polypropylene has emerged as one of the fastest-growing segments within the polypropylene product category.

Transparent polypropylene, known for its exceptional clarity and gloss, rivals typical transparent materials like PET, PVC, and PS. It finds wide application in household items, packaging, and medical fields, thanks to its high toughness, rigidity, heat resistance, and outstanding chemical resistance. To enhance the market value of polypropylene, transparent modification plays a crucial role. Among the numerous factors influencing the transparency of polymer materials, refractive index, crystallinity, crystal size, and surface roughness stand out as key elements.

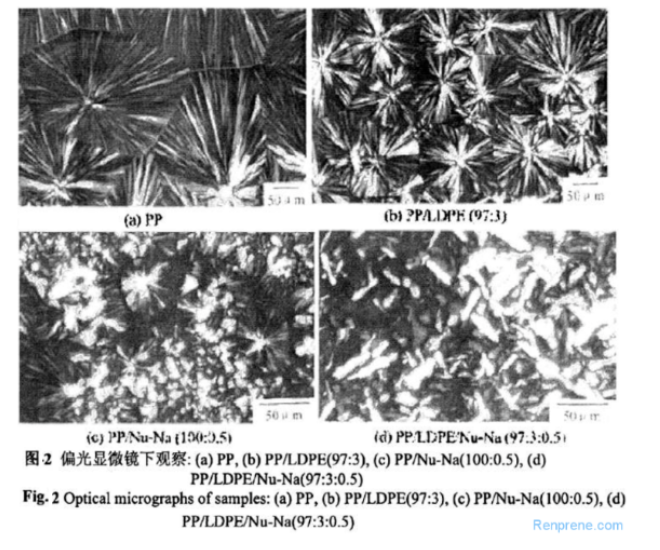

According to insights from the Color Masterbatch Industry Network, the transparent modification of polypropylene primarily focuses on reducing crystallinity and crystal size. Polypropylene is partially crystalline, with a crystallinity ranging from 50% to 60%, featuring both crystalline and amorphous regions in its aggregated structure. To improve transparency, it is essential to decrease crystallinity and expand the amorphous region, while also reducing crystal size. Current methods to enhance polypropylene’s transparency include the addition of transparency agents, the synthesis of random copolymers, the use of metallocene catalysis for transparent polypropylene synthesis, the blending of transparent polypropylene, and process control.

In terms of adding transparency agents, incorporating such agents into polypropylene can promote the formation of more microcrystals during melting and crystallization, reducing the number of spherulites and thereby refining crystal size, ultimately enhancing the resin’s transparency. Sorbitol-based nucleating agents, particularly, have been widely adopted in polypropylene transparent modification due to their effective transparency-enhancing properties. Additionally, methods such as synthesizing random copolymers, using metallocene catalysis, and blending transparent polypropylene have also yielded notable modification results.

Overall, with the continuous development and technological advancements in the transparent polypropylene industry, its application scope is poised to further expand, presenting a promising market outlook. In the future, transparent polypropylene will continue to play a vital role in various sectors, bringing more convenience and beauty to people’s lives.