February 23, 2025 – A novel composite pipe material, known as the Multi-Reinforced Steel-Plastic Composite Pressure Pipe, has recently garnered significant attention. Utilizing a unique manufacturing process, this pipe seamlessly integrates steel and plastic materials, resulting in a high-performance composite.

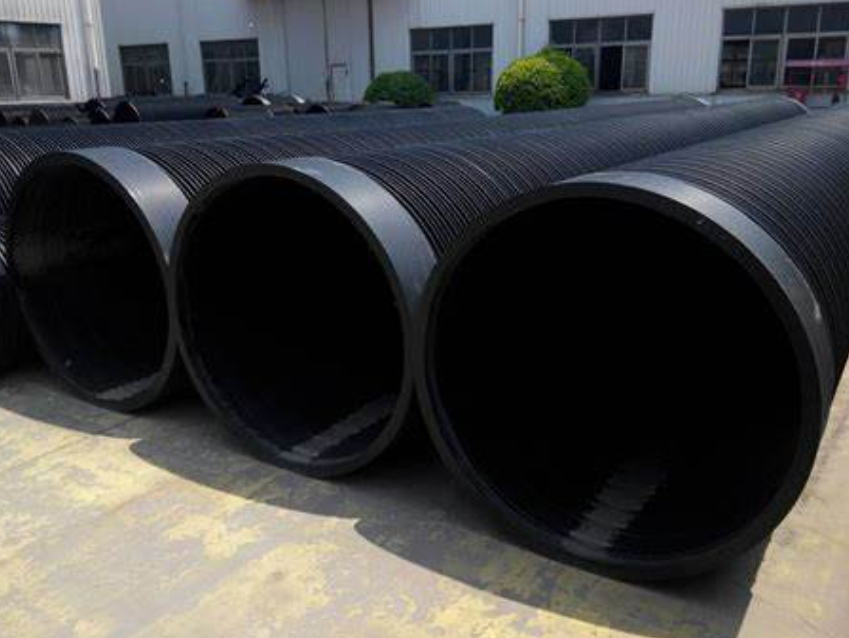

The structural design of this composite pressure pipe is ingeniously crafted, featuring a plastic lining on the inside, multiple layers of steel strips wound tightly for reinforcement in the middle, and an outer plastic protective sheath. Each layer serves a distinct purpose, collectively contributing to the pipe’s exceptional overall performance. The steel reinforcement layer acts as the “backbone” of the pipe, significantly enhancing its strength and pressure resistance, allowing it to maintain stability even in high-pressure environments.

According to industry insights from the Color Masterbatch Network, the plastic lining leverages its chemical resistance and low fluid friction properties, ensuring efficient and stable fluid transportation. Meanwhile, the outer plastic sheath serves as a “shield,” effectively protecting the steel strips from environmental corrosion, thereby significantly extending the pipe’s service life.

With its high strength, excellent pressure resistance, superior corrosion resistance, low fluid resistance, convenient installation, and low maintenance costs, the Multi-Reinforced Steel-Plastic Composite Pressure Pipe has swiftly found widespread application in medium to high-pressure pipeline systems across various sectors, including water supply and drainage, oil and gas, chemicals, and mining. The emergence of this innovative material undoubtedly offers a superior and more efficient solution for pipeline construction across multiple industries.