June 4, 2025 – China’s special polymer materials sector has achieved a major breakthrough with the recent commissioning of the Chongqing production base of Wotefoam. The milestone marks a significant leap in the country’s self-sufficient capability in core materials for strategic emerging industries such as 5G communications and artificial intelligence.

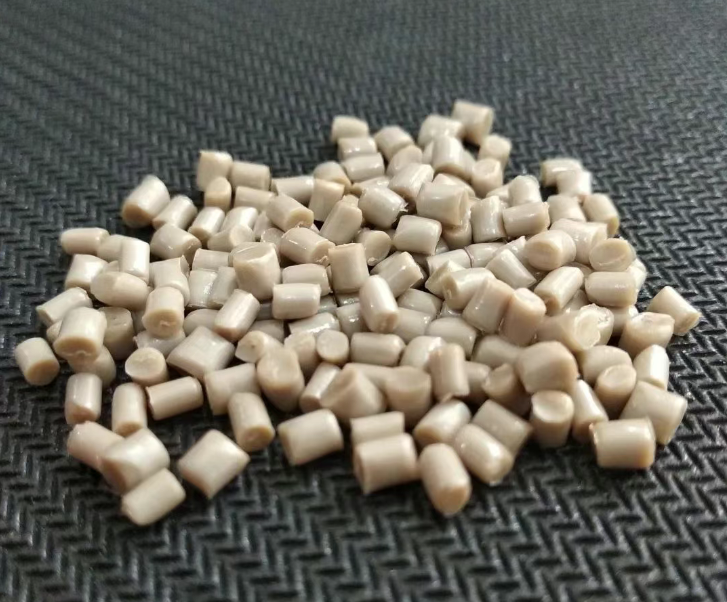

The newly operational Chongqing Wotefoam Zhicheng project features two production lines: an annual 20,000-ton LCP (liquid crystal polymer) resin material line and a 1,000-ton PAEK (polyaryletherketone) resin material line. With full capacity utilization, Wotefoam’s total LCP production capacity will reach 25,000 tons, positioning the company to potentially become the world’s largest LCP material supplier.

According to the Color Masterbatch Industry Network, Wotefoam has established a full industrial chain layout from LCP resin synthesis to film and fiber products through a introduction-digestion-innovation development path. After acquiring Samsung’s LCP production line in South Korea in 2014, the company built an LCP production line with complete independent intellectual property rights in 2020 and achieved the top domestic sales volume in 2021.

In raw material supply, Chinese enterprises have made notable breakthroughs. Companies like Sichuan Shengxiao and Shandong Kunda have solved the large-scale production challenges of 4,4′-biphenol, providing a solid foundation for the localization of LCP materials. This achievement has effectively reduced domestic industries’ reliance on imported raw materials.

Beyond LCP, Wotefoam has made significant progress in the PAEK resin field. Adopting a full-chain development model of “synthesis-modification-profiles,” its first-phase PAEK synthetic resin production line has entered the trial production stage and secured partnerships with clients in medical and electronics sectors. This vertical integration gives Wotefoam a unique advantage in China’s special engineering plastics industry.

Wotefoam’s five national production bases all possess strong R&D capabilities. Subsidiaries in Huizhou, Jiangsu, Zhejiang, and other regions are recognized as national high-tech enterprises, holding multiple core patents and technical platforms. Such a comprehensive industrial layout provides a robust foundation for the company’s continuous innovation.

With the rapid development of industries like 5G communications, AI, and semiconductors, the market demand for high-performance polymer materials is steadily increasing. Wotefoam’s capacity expansion comes at an opportune time, poised to play a critical role in these strategic emerging sectors and drive China’s high-end manufacturing from “import substitution” to “standard-setting.”