May 19, 2025 – Amid escalating global plastic pollution and the pursuit of “dual carbon” goals, Shanghai Bluepha Biotechnology Co., Ltd., in collaboration with renowned academic institutions such as Fudan University and the University of Oxford, has achieved three pivotal breakthroughs in polyhydroxyalkanoate (PHA) biomanufacturing technology. These achievements include setting a new world record of 300 grams per liter in single-tank production, reaching a 100% carbon source conversion rate, and slashing the carbon footprint by 64%. The research outcomes, published in esteemed international journals like Metabolic Engineering and Resources, Conservation and Recycling, firmly establish China’s leading position in the biomanufacturing field.

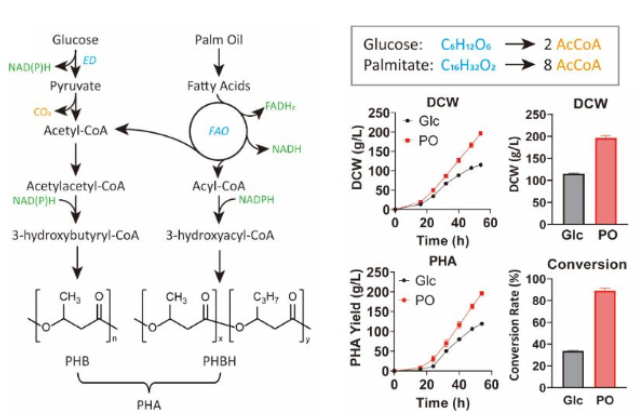

PHA, a natural polymer synthesized by microorganisms, boasts remarkable properties such as rapid biodegradability, biocompatibility, and thermoplasticity. It degrades 100 times faster than conventional plastics, naturally breaking down into carbon dioxide and water. Despite these eco-friendly attributes, large-scale PHA production has long been hampered by technical hurdles. In the 1980s, Imperial Chemical Industries (ICI) in the UK attempted commercializing PHA but failed due to exorbitant production costs. Bluepha’s R&D team, leveraging genetic engineering techniques, has now unlocked a new pathway using oil-based raw materials, enabling industrial-scale PHA production.

Traditional PHA manufacturing, relying on sugar-based feedstocks, suffered from low carbon source conversion rates and high costs. However, Bluepha’s team utilized an industrially optimized Ralstonia eutropha strain, achieving a PHA concentration of 264 grams per liter in a 150-ton production facility. This feat not only exceeded a 100% carbon source conversion rate but also reduced production costs by 28% to $590 per ton. Further process enhancements pushed the production yield to 300 grams per liter, rewriting global industrial production records. As AsiaMB has learned, this breakthrough paves the way for PHA’s widespread application, from high-value medical devices to everyday products like packaging materials, tableware, and textile fibers.

Bluepha’s innovation extends to its proprietary Biohybrid technology system, which marks two significant advancements. Version 1.0 activated the Calvin cycle in industrial strains for the first time, recycling metabolic byproducts and sequestering carbon dioxide to boost fermentation yields. Version 2.0, integrating functional genomics and synthetic biology, further optimized the strain’s lipid utilization capabilities, elevating production yields beyond 300 grams per liter and maintaining over 100% carbon source conversion. Coupling food waste-derived oil with Biohybrid 2.0, Bluepha has significantly minimized PHA’s carbon footprint, setting a new environmental benchmark for biodegradable materials.

With conventional plastics taking centuries to decompose and posing severe ecological threats, PHA’s ability to biodegrade within weeks to months offers a viable solution to the global plastic pollution crisis. Bluepha’s technological triumphs not only resolve longstanding PHA production challenges but also establish a comprehensive framework spanning laboratory research to industrial application, injecting fresh momentum into the biomanufacturing industry.