May 21, 2025 – Declining articular cartilage lubrication, akin to mechanical parts losing lubricant, accelerates cartilage wear and triggers osteoarthritis, severely impacting patients’ mobility. For years, medical and materials science fields have pursued materials mimicking natural joint lubrication. Recently, the State Key Laboratory of Lubricating Materials at the Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, achieved a breakthrough: developing PVA/CS (polyvinyl alcohol/chitosan) hydrogels with both high mechanical strength and exceptional lubricity, published in Advanced Functional Materials.

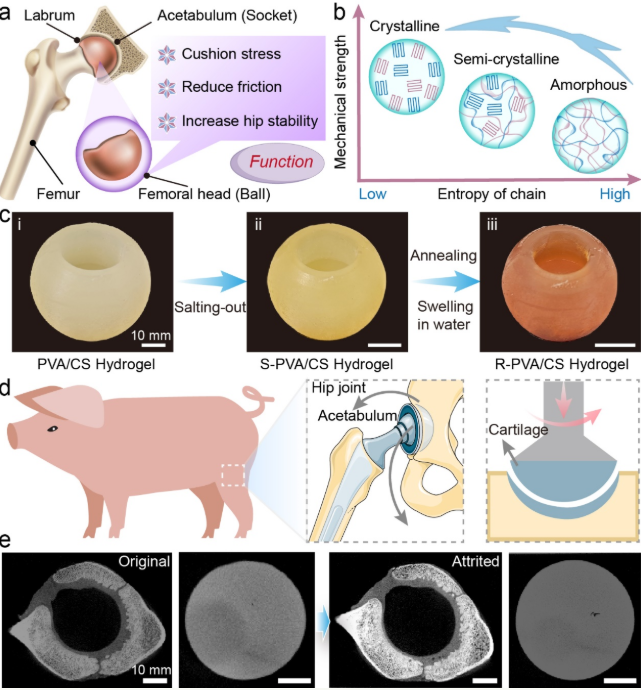

Hydrogels are regarded as ideal articular substitute materials due to their cartilage-like softness and biocompatibility. However, traditional hydrogels often suffer from mechanical degradation and lubrication failure under long-term external forces, limiting their use in high-load scenarios. To address this bottleneck, the team introduced a “low-entropy nanocrystalline domain network regulation” strategy, precisely controlling the ratio of high-entropy amorphous and low-entropy crystalline structures within the hydrogel to create a novel material combining mechanical robustness and lubrication durability.

Industry insights from the Color Masterbatch Industry Network highlight the strategy’s innovation in integrating microstructural regulation with macro-performance optimization. The team analogizes high-entropy amorphous structures to “disordered skirmishers” and low-entropy crystalline structures to “ordered phalanxes,” designing intermolecular interactions and energy state regulation to form a “rigid-flexible integrated” nanocrystalline domain network. This structure ensures energy dissipation under stress while maintaining lubrication interface stability, synergistically enhancing mechanical strength and lubricating properties.

Experimental data show the optimized PVA/CS hydrogels exhibit a fracture strength of 7.7–17.5 MPa, elastic modulus of 8.6–10.6 MPa, toughness of 8.8–62.1 MJ/m³, indentation hardness of 10.4–21.7 MPa, and a low friction coefficient of 0.026 with excellent lubrication durability. In tests simulating human weight-bearing environments, the hydrogels demonstrate superior wear resistance, particularly in artificial hip joint applications, where their lubrication performance approaches that of natural cartilage—providing a technical paradigm for developing next-generation high-performance artificial joint lubrication materials.

This achievement not only overcomes the industry challenge of traditional hydrogels cracking or deforming under high loads but also opens new avenues for joint repair and biological lubrication. With further performance validation and clinical translation, these materials may significantly improve treatment options for osteoarthritis patients, accelerating the development of biomedical materials toward “biomimetic-functional integration.”