June 12, 2025 –

AsiaMB Exclusive: Israeli Breakthrough in Reversible Adhesives Could Revolutionize Plastic Assembly

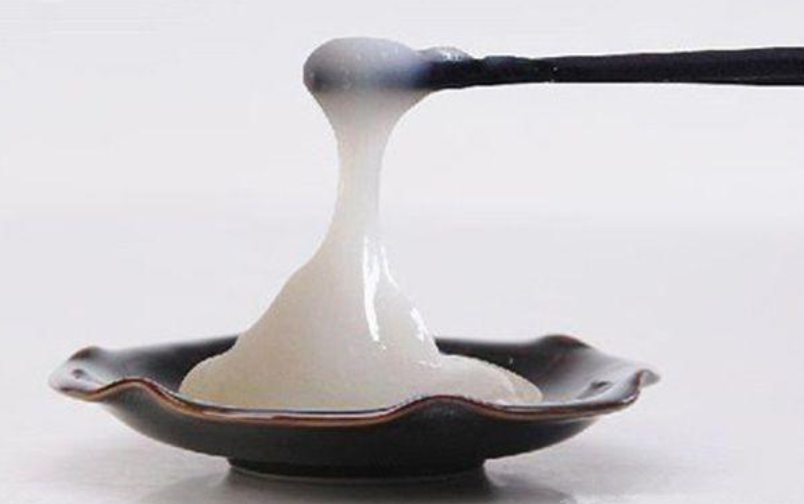

Researchers at Jerusalem’s Hebrew University have developed a game-changing adhesive technology that could transform how plastics are assembled and recycled. The innovation holds particular significance for the masterbatch industry, where bonding and disassembly processes often complicate material recovery.

The novel adhesive system, based on α-lipoic acid (ALA) chemistry, offers unprecedented capabilities:

• Cures in 30 seconds under visible light (400-650nm)

• Releases bonds via standard microwave exposure

• Maintains optical clarity critical for transparent applications

• Performs equally well after multiple reuse cycles

“This isn’t just another adhesive – it’s a paradigm shift in material joining,” explained lead researcher Dr. Amit Cohen. “For masterbatch applications, it enables clean separation of compounded materials during recycling without compromising polymer integrity.”

Key advantages over conventional adhesives include:

- No high temperatures, solvents or UV required

- Underwater bonding capability

- 90%+ material recovery rate

- Strong adhesion across diverse substrates

The technology, detailed in Advanced Materials, could particularly benefit:

- Multi-material packaging with different masterbatch formulations

- Electronics components requiring temporary bonds during manufacturing

- Medical devices needing sterilization-compatible adhesives

Industry analysts note this development aligns perfectly with growing demand for circular material solutions. “Imagine being able to disassemble a colored plastic product and recover both the base polymer and masterbatch components separately,” commented AsiaMB’s technology editor.

The research team is now collaborating with industrial partners to scale up production and optimize recycling protocols. As sustainability regulations tighten globally, such reversible bonding solutions may soon become standard in plastic product design.