November 20, 2024 – Polypropylene (PP) and Polyethylene (PE): The Dynamic Duo of Plastics Unveiled

Plastics, an omnipresent material in our daily lives, grace everything from kitchen utensils to medical equipment. Among the plastic elite, Polypropylene (PP) and Polyethylene (PE) stand out as the stars. But what are the differences and similarities between these two giants of the plastic world?

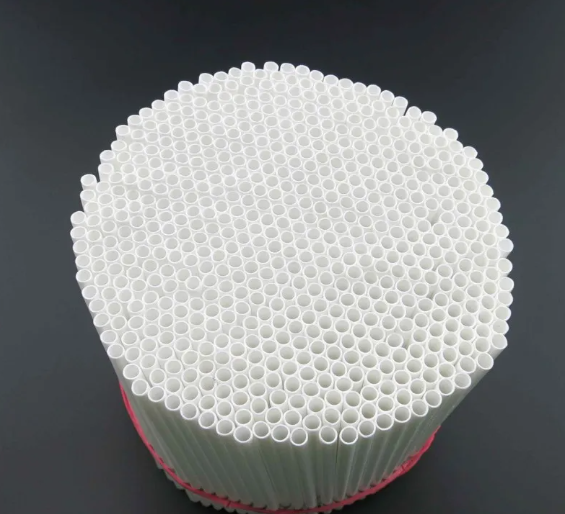

PP, renowned for its lightness and heat resistance, is a familiar face in food containers and automotive parts. Its chemical formula, (C3H6)n, hints at its excellent chemical stability and electrical insulation properties. Conversely, PE, with its flexibility and low-temperature resistance, is a staple in packaging films and insulating layers.

Delving deeper, the chemical structure divergence lies in their polymerization units. PP is derived from propylene, while PE originates from ethylene. Meanwhile, PE’s softness and low-temperature resilience shine in frozen food packaging.

These distinct characteristics naturally carve out unique application niches for each. In food heating, PP containers can withstand temperatures exceeding 100 degrees Celsius, making microwave heating safe and convenient. PE’s flexibility and cold resistance make it the go-to choice for frozen food packaging, maintaining performance even at sub-zero temperatures to ensure food freshness and safety.

In the medical field, PP’s high melting point makes it ideal for medical devices and lab containers, while PE’s chemical resistance safeguards drug integrity. According to Color Masterbatch Industry News, PP’s hardness and wear resistance make it a top pick for children’s toys and household storage boxes, while PE’s softness and transparency enhance the practicality of plastic films and shopping bags.

On the environmental front, PP’s easy recyclability showcases its green credentials, aiding in pollution reduction. Although PE recycling is more challenging, advancements are steadily improving its recycling rates. Furthermore, PP’s malleability allows for intricate product shapes, while PE’s moisture resistance makes it a prime candidate for waterproof materials.

Historically, the invention and application of PP and PE have propelled modern industrial development. From lab experiments to mass production, their journey reflects humanity’s relentless exploration of materials science. Looking ahead, with the advent of nanotechnology and other innovations, we may witness even lighter, stronger, and more eco-friendly PP and PE materials, unlocking new possibilities for our lives.

When choosing plastic products, understanding the nuances between PP and PE is not just a daily decision but also a matter of environmental responsibility and stewardship.