February 20, 2025 – Mitsui Chemicals and comprehensive hair salon service provider ARTNATURE have recently announced a groundbreaking collaboration to produce custom wig molds using bio-based polyurethane materials starting from February 2025. This innovative move is set to revolutionize the wig manufacturing industry.

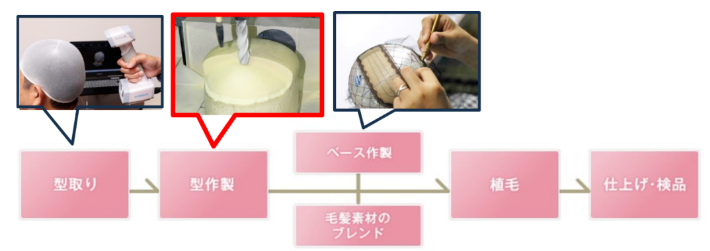

In the production process of custom wigs, 3D scanners are first used to precisely capture the shape of a customer’s head. This data is then utilized to trim the polyurethane material, creating a mold that perfectly fits the customer’s head. Polyurethane is an ideal choice for such molds due to its excellent dimensional stability and ease of processing. Based on the precise shape of the mold, the cap for the wig base is crafted, and individual hairs are meticulously added to the cap to complete the wig.

According to industry insights from AsiaMB, the polyurethane materials traditionally used in wig mold production are primarily derived from petroleum. However, the partnership between Mitsui Chemicals and ARTNATURE introduces a bio-based material sourced from non-edible castor oil (with a bio-content of up to 20%). This shift not only helps reduce waste generation during production but also significantly lowers CO2 emissions during incineration. It is estimated that this change will lead to a reduction of approximately 12 tons of waste and up to 70 tons of CO2 emissions annually, marking a 50% reduction in emissions.

Moreover, the application scope of polyurethane materials has been expanding recently, with notable advancements in cutting-edge technology. Stay tuned to our coverage for more groundbreaking applications of polyurethane materials.