June 13, 2025 –

Breakthrough in Electronic Waste Recycling: JEPLAN Transforms MLCC Waste into Premium PET Raw Material

AsiaMB reports a revolutionary advancement in plastic circularity from Japan’s JEPLAN Corporation. The pioneering recycling specialist has successfully converted discarded PET films from multilayer ceramic capacitor (MLCC) manufacturing into high-purity BHET through innovative chemical recycling technology – a world-first achievement with significant implications for the masterbatch industry.

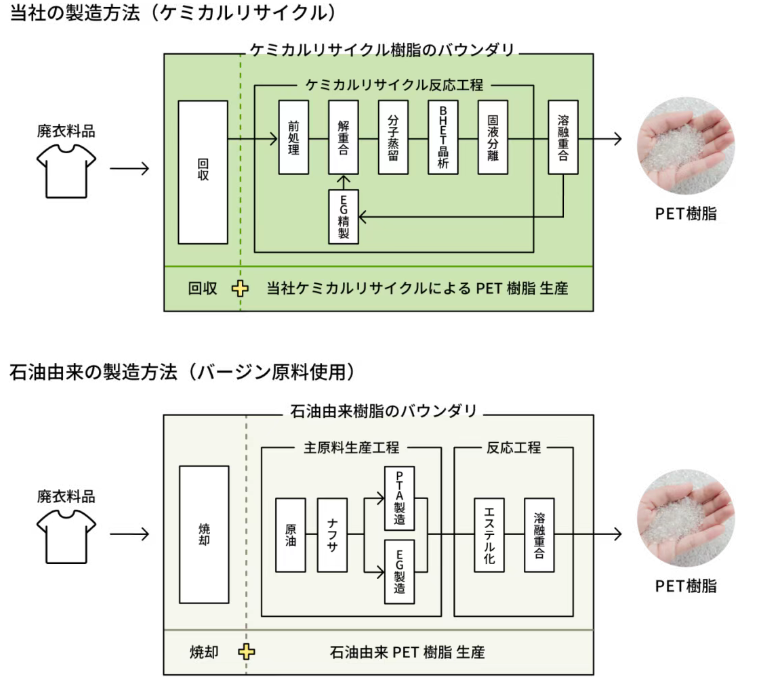

The breakthrough addresses a longstanding environmental challenge in electronics production. MLCC manufacturing typically renders PET films unrecyclable due to ceramic contamination. JEPLAN’s proprietary chemical process achieves molecular-level purification, producing BHET that matches virgin petroleum-based PET in quality – suitable even for demanding applications like food-grade packaging and technical fibers.

This chemical recycling method offers distinct advantages over conventional mechanical processes:

• Complete removal of ceramic residues and other contaminants

• Preservation of PET’s molecular structure integrity

• Capability to produce materials for high-end applications

• Potential 40% reduction in carbon footprint compared to virgin PET production

The technology builds on JEPLAN’s established PET bottle-to-bottle and fiber-to-fiber recycling systems. Its expansion into industrial PET waste streams demonstrates growing technical sophistication in chemical recycling. The company has announced plans for commercial-scale implementation by 2026, with potential applications extending to cosmetic containers and other complex PET products.

Industry experts highlight this development as particularly relevant for color masterbatch producers, who increasingly demand high-quality recycled materials to meet sustainability targets. The breakthrough could significantly reduce the electronics sector’s reliance on fossil-based plastics while maintaining performance standards – a critical balance for sustainable manufacturing.

As global regulations push for greater circularity in plastics, JEPLAN’s innovation provides a scalable model for closing industrial plastic loops. The achievement underscores Japan’s leadership in advanced recycling technologies and offers new possibilities for sustainable materials in electronics and related industries.