September 28, 2024 – Chengdu’s green recycling sector has taken a significant leap forward with the official commencement of construction for the Chengdu Green Recycling Intelligence Industrial Park (Phase I) on September 23rd. This marks the inception of the first food-grade recycled PET production base in the Chengdu-Chongqing region of Southwest China.

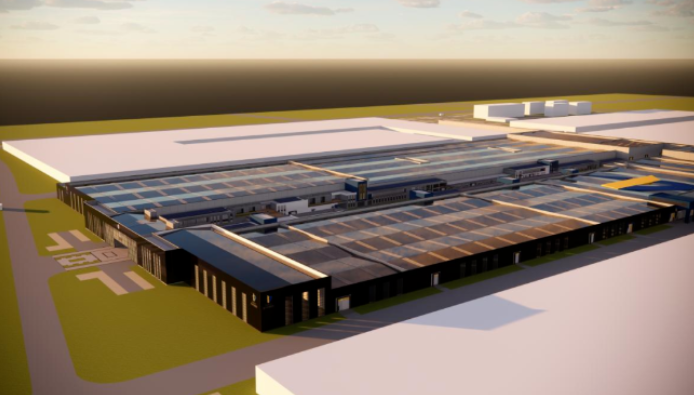

Nestled within the picturesque Tianfu Smart Manufacturing Industrial Park in Xinjin District, the industrial park spans an impressive 72 acres. The project encompasses not only the production and processing of food-grade recycled PET flakes but also extends to the manufacturing processes of upstream and downstream derivative industries in the recycling sector. It aims to establish a comprehensive closed-loop circular economy model that integrates resources, products, waste, and recycled resources. Reportedly, the park is anticipated to commence trial operations in May 2025, injecting new vitality into Chengdu’s and the broader Southwest region’s green recycling industry.

According to insights from ColorMasterbatchIndustry.com, the industrial park has achieved remarkable technological innovations. The park will introduce advanced domestic and foreign technologies for waste material recovery, sorting, and processing, particularly focusing on cleaning, pelletizing, and solid-state polycondensation techniques for waste polyester flakes to ensure product quality meets food-grade standards. This technology not only transforms plastic from waste into high-end recycled resources but also systematically replaces primitive and extensive recovery, sorting, and processing methods, thereby driving structural adjustments and optimization in the recycling industry. Relevant park officials have stated that they adopt industry-proven production processes recognized by international food-grade recycled PET certification agencies to manufacture high-quality recycled PET flakes. They also strengthen communication and collaboration with downstream enterprises demanding high-value utilization, aiming to realize high-value realization of supplied and marketed products. The anticipated annual full production capacity is approximately 40,000 tons, unearthing substantial new benefits from “old” plastics.

Furthermore, the industrial park actively embraces the concept of green and low-carbon by transforming factory rooftops into “power stations.” Through the construction of an integrated green energy project combining photovoltaic and energy storage, the park not only aids enterprises in energy conservation and emission reduction but also further supports the development of a “low-carbon park.” According to relevant officials from HuanTou Recycling Technology Company, the photovoltaic project will fully leverage the low-rise structural characteristics of the factory buildings, adopting cadmium telluride photovoltaic building-integrated technology to install photovoltaic and energy storage facilities. The estimated installed capacity will reach 3.1 MWp, accompanied by a 2,000 kW energy storage system. Calculations indicate that this project can reduce approximately 3,000 tons of carbon dioxide emissions annually, contributing to the realization of carbon neutrality goals.

With the continuous advancement of the Chengdu Green Recycling Intelligence Industrial Park project, we have reason to believe that, in the coming days, this industrial park will become a shining star in the green recycling industry of Southwest China, making positive contributions to promoting the development of China’s green circular economy.