May 6, 2025 – Ascend Performance Materials, a globally renowned producer of polyamides, made a significant announcement on April 22. With the strong support of key stakeholders such as some existing creditor institutions, it has formally submitted an application to the United States Bankruptcy Court for the Southern District of Texas, initiating the Chapter 11 reorganization process. This process aims to reduce the company’s asset – liability leverage ratio, ensuring that while Ascend Performance Materials adjusts its financial structure, it can continuously provide high – quality and top – notch products to nearly 1650 customers worldwide.

It should be noted that the scope of this Chapter 11 process application does not cover Ascend Performance Materials’ subsidiaries and production bases outside the United States. According to AsiaMB, the Chapter 11 process, derived from the reorganization chapter of the United States Bankruptcy Code, is characterized by providing the company with a certain period of time under the protection of the court. During this period, the company can carry out reorganization in an orderly manner while continuing to operate, thus coping with the financial challenges it faces. With the support of creditor institutions, Ascend Performance Materials will make full use of this process to conduct value – maximizing reorganization.

Ascend Performance Materials clearly stated that this reorganization is of great significance to the company. It will significantly reduce the company’s debt and help it better promote its long – term strategic plan. It is a crucial step for the company to actively meet challenges and move towards high – quality development. After the reorganization is completed, the company’s capital structure will be significantly optimized, and its risk – resistance and market competitiveness will be further enhanced, transforming it into a healthier and better – capitalized enterprise. Currently, the company has successfully obtained a financing commitment of $250 million from some creditor institutions, which will inject sufficient liquidity into the company throughout the reorganization process and ensure that the company’s operations are not affected. As planned, Ascend Performance Materials aims to complete the entire reorganization process in approximately six months.

Ascend Performance Materials also emphasized that the initiation of the Chapter 11 process does not mean business suspension. The company will maintain normal operations during the reorganization process, and production, shipping, and product delivery will all proceed as usual. Moreover, it will continue to focus on creating high – quality and high – performance products for customers. In addition, Ascend Performance Materials has submitted a “first – day motion” to the court, seeking the court’s approval for the company’s operational support during the reorganization, including the uninterrupted payment of employee salaries and benefits. It is expected that this motion will be approved by the court in the next few days. After the reorganization is completed, the creditors (leading investment institutions) will become the new shareholders of Ascend Performance Materials, while the company’s management team will remain unchanged and continue to lead the company to complete the reorganization and future development tasks.

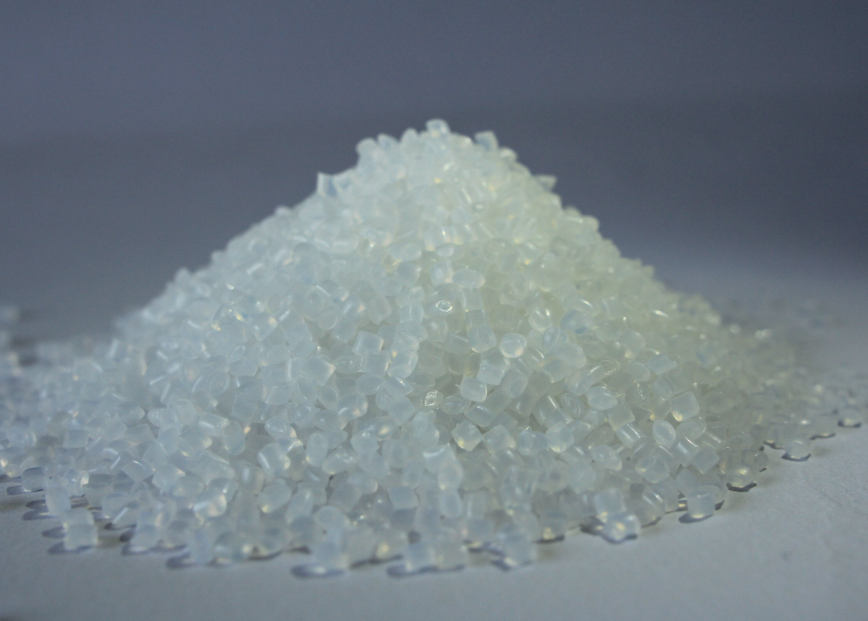

Ascend Performance Materials has an extensive and in – depth layout in the nylon industry chain. As an upstream – downstream integrated polyamide producer, it has 12 production bases globally and nearly 3000 employees. The company is headquartered in Houston, Texas, USA, and has regional headquarters and research and development centers in Asia, Europe, and the Americas. Its products are widely used in many industries, including automotive, electronics and electrical, industrial fibers, and consumer goods. In terms of production capacity, Ascend Performance Materials’ nylon 66 polymerization capacity reaches 700,000 tons per year. As early as 2020, Ascend Performance Materials further expanded its nylon 66 production and research and development business in China by acquiring Changshu Hobson New Material Co., Ltd. and Tehe Engineering Plastics Co., Ltd. In the field of adiponitrile, Ascend Performance Materials currently has an adiponitrile production capacity of 490,000 tons per year. And in July 2023, news spread that its US factory would add an additional 90,000 tons per year of adiponitrile production capacity by 2025, and the total production capacity will reach 580,000 tons per year. In the field of hexamethylenediamine, in October 2024, the 200,000 – ton – per – year hexamethylenediamine project in Lianyungang Petrochemical Industry Base opened, bringing its hexamethylenediamine production capacity to approximately 600,000 tons per year. However, it is worth mentioning that in October last year, Ascend Performance Materials’ largest adipic acid base in the United States experienced a layoff incident.

Currently, the global nylon industry is in a stage of restructuring. Affected by various factors such as competition, cost, and environmental protection, overseas nylon giants have adjusted their related businesses in recent years. In February this year, the nylon giant RadiciGroup sold its specialty chemicals and high – performance polymers business to the US private equity fund Lone Star. In January this year, Ube Industries, Ltd. of Japan announced that the production of caprolactam (the remaining key production line) and nylon polymers at its Japanese chemical plant would cease at the end of the 2026 fiscal year (March 2027). Its factory in Thailand, Ube Industries (Asia) Chemical Co., Ltd. (UCHA), will also stop the production of cyclohexanone, caprolactam, and ammonium sulfate and close one of the two nylon polymer production lines at the end of the 2026 fiscal year (March 2027). Prior to this, chemical giants such as BASF, Sumitomo Chemical, and Mitsubishi Chemical also announced the closure of some nylon – related production lines.

In sharp contrast to the reduction of nylon – related business production lines by overseas chemical giants, the domestic nylon production capacity in China has now entered a period of rapid growth. In the nylon 6 field, in recent years, with the progress of polymerization technology and the breakthrough in the production technology of raw material caprolactam, the nylon 6 industry has ushered in unprecedented development opportunities. Currently, there are as many as 44 major producers of nylon 6 in China. Enterprises such as Hoshine Group, Luxi Chemical, PolyMax, Hengyi Petrochemical, Pingmei Shenma, and Yongrong Jinjiang all have a production capacity of over 400,000 tons per year. In the nylon 66 aspect, the world’s major producers include Invista, Ascend Performance Materials, BASF, Shenma Co., Ltd., RadiciGroup, and Asahi Kasei.