October 18, 2024 – Ampacet, a global leader in the chemical industry, has unveiled two groundbreaking products: Halolite 527, a low-halogen flame retardant masterbatch, and Halofree 533, a halogen-free flame retardant masterbatch. These innovative offerings strictly adhere to the international standards IEC 61249-2-21 and EN 50642, rigorously controlling the content of halogens and antimony to cater to the market’s demand for safer and more eco-friendly materials.

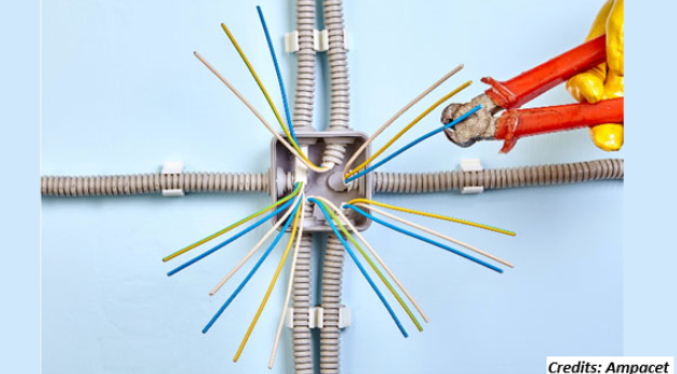

In the manufacturing of electrical equipment, particularly within the construction and building industries, excellent fire resistance is paramount in ensuring product safety. Traditional flame retardants, while effective in enhancing material’s flame retardancy, may release toxic and corrosive gases during combustion, posing threats to both the environment and human health.

To tackle this challenge, Ampacet has meticulously developed Halolite 527 and Halofree 533. These masterbatches not only comply with the latest international flame retardant standards but also feature low-halogen and halogen-free formulations, respectively. They are particularly suited for polypropylene (PP) materials used in electrical equipment and other PP injection molding or extrusion plastic products widely applied in construction and building. By meeting the UL94 V2 classification standard and boasting a high glow wire flammability index (GWFI), these products offer the industry a safer and more reliable flame retardant solution.

Moreover, both Halolite 527 and Halofree 533 come in natural colors, allowing users to add individual color masterbatches as per their requirements. Ampacet also provides pre-colored versions tailored to specific customer needs, addressing the market’s diverse demands.