November 26, 2024 – Ester Industries Embraces Green Transformation with Advanced Recycling System in Hyderabad

In line with the global shift towards sustainability, the packaging industry in India is witnessing new avenues of growth. Ester Industries, a pioneering force in polyester (PET) film production, has announced the integration of the cutting-edge Gneuss OMNI 200 recycling system at its new manufacturing facility in Hyderabad. This move aligns perfectly with India’s ambitious 2025 circular economy goals and sets a new benchmark for the green packaging sector worldwide.

The Indian government has been relentless in its pursuit of a circular economy, aiming to establish comprehensive waste collection and recycling infrastructure by 2025. Coupled with the enforcement of Extended Producer Responsibility (EPR) policies, these measures seek to boost the market demand for recycled materials and promote their widespread use. Ester Industries, which has been at the forefront of high-value and specialty product development since its inception, exports its products to 85 countries globally.

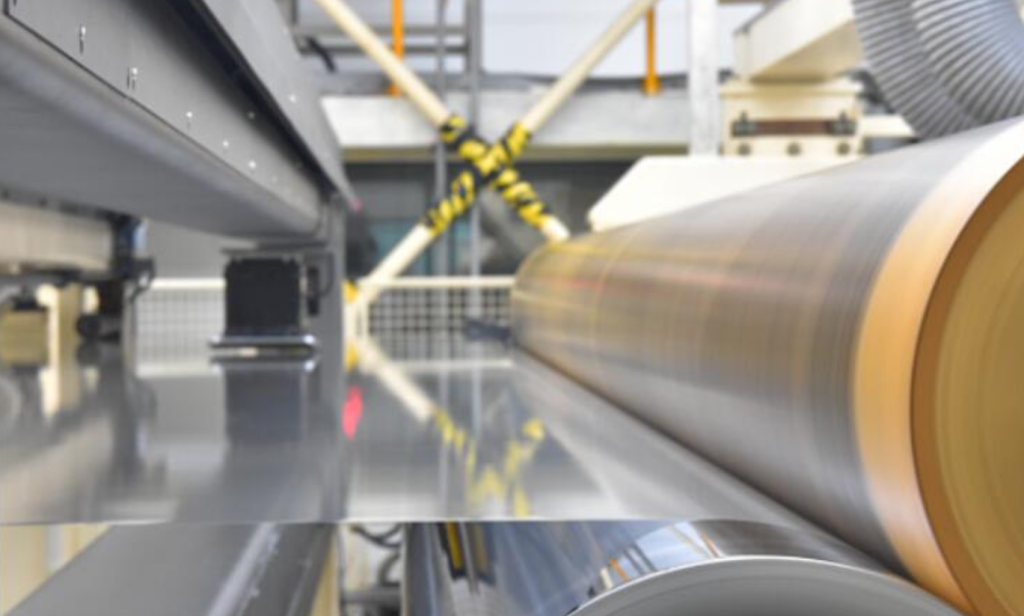

The Gneuss OMNI 200 recycling system chosen by Ester Industries stands out as a leader in recycling technology. According to industry sources, this system efficiently processes 2,000 kilograms of bottle flakes per hour, directly converting them into food-grade pellets for BOPET (biaxially oriented polyester) film production. Unlike traditional methods, the OMNI 200 system eliminates the need for pre-drying and crystallization, significantly reducing energy consumption while ensuring a gentler processing approach.

Its 3C rotary feeder ensures a consistent feed to the extruder, while the MRS extruder effectively removes contaminants from the polymer melt, meeting stringent standards for direct food contact. Furthermore, the dual precision filtration system guarantees exceptional film quality and minimizes material waste. Notably, the ‘no pre-drying’ design of the OMNI 200 not only shortens the raw material’s exposure to heat but also extends the lifespan of the filter screens, even when handling post-consumer waste.

Ester Industries anticipates that the introduction of this system will yield substantial economic and environmental benefits, including energy savings, minimized material wastage, and continuous product quality improvement. Gneuss’ innovative technology will also empower Ester Industries to better navigate the increasingly stringent environmental regulations in India and globally, providing robust support for its green transformation.

The investment is expected to reach full operational capacity between mid to late 2025. By then, the Gneuss OMNI 200 system will become the cornerstone of Ester Industries’ BOPET film production, delivering high-quality and sustainable packaging solutions to the Indian and global markets. This initiative not only underscores Ester Industries’ steadfast commitment to sustainability but also injects fresh impetus into the development of the global green packaging industry.