August 22, 2024 – Heavy calcium carbonate, a powder product processed from natural minerals such as calcite, marble, limestone, and chalk, has recently garnered significant attention. This versatile material can be tailored to meet the fineness requirements of various application fields through specialized processing techniques.

In the production of heavy calcium carbonate, the dry process method is extensively used to manufacture products with a fineness of d97≥3-5μm. A wide range of crushing equipment is employed, including Raymond mills, impact crushers, dry agitator bead mills, jet mills, vertical mills, roller mills, vibrating mills, and ball mills.

According to the Color Masterbatch Industry Network, the Raymond mill is a commonly used device in the production of heavy calcium carbonate, extensively applied to produce particles sized 38-74μm (200-400 mesh). Technical modifications and the integration of precision classifiers have enabled the production of finer powders with a d97 of 30-15μm (500-800 mesh). The Raymond mill is favored for its small footprint, high product screening rate, strong systematicness, and reliable operation. However, it faces challenges such as a low volume fraction of 2μm fine powder and a small specific surface area.

The process of using a ball mill coupled with a classifier is recommended by leading powder technology companies worldwide and is widely adopted by several renowned powder companies in Europe and America. This method can produce multiple grades of heavy calcium carbonate products, such as d97=5μm, 10μm, 16μm, and 45μm. Nevertheless, it has drawbacks, including a high volume fraction of 2μm fine powder, an excessively large specific surface area leading to particle agglomeration and poor product dispersion, and high energy consumption per ton of product.

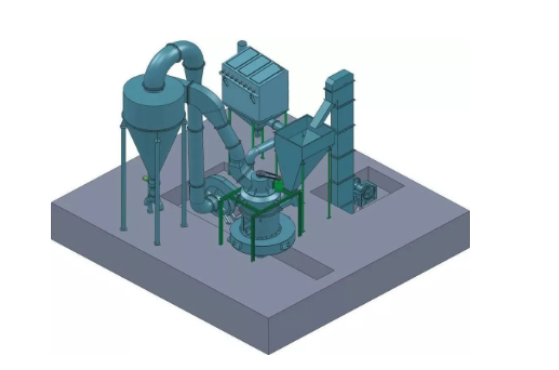

In recent years, significant progress has been made in the fine processing technology of heavy calcium carbonate powder through the use of vertical mills with secondary and tertiary classification in the dry process. The vertical mill employs relative movement between the grinding roller and the grinding disc to crush the material in a bedded manner, directly processing ordinary heavy calcium carbonate ranging from 325 to 800 mesh. Additionally, by incorporating classification equipment, some products can undergo secondary or tertiary classification to produce medium and high-grade fine powders ranging from 1000 to 2500 mesh. For lower-grade products, wet mills or jet mills can be utilized for fine grinding to meet the high-end demand for ultra-fine powders ranging from 2500 to 6500 mesh.