June 23, 2025 – AsiaMB Exclusive: Eastman’s Molecular Recycling Revolution Transforms Plastic Waste Management

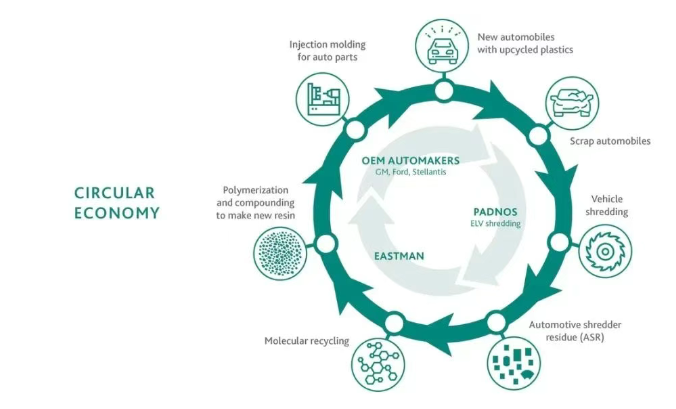

In a groundbreaking development for the plastics industry, Eastman Chemical Company has pioneered an advanced molecular recycling technology that’s setting new standards for circular economy solutions. This innovative approach chemically breaks down post-consumer plastic waste into molecular building blocks, enabling the production of premium-quality recycled materials comparable to virgin plastics.

AsiaMB has learned that Eastman’s methanolysis facility in Kingsport, Tennessee, has achieved stable operations with capacity to process over 110,000 metric tons of complex plastic waste annually. The technology delivers dual benefits – creating high-value materials for demanding applications while reducing carbon emissions by 20-30% compared to conventional production methods.

The company has successfully commercialized its RecyClass-certified recycled polymers through partnerships with luxury brands including Estée Lauder and Procter & Gamble. These materials now feature in high-end cosmetic packaging, offering exceptional clarity and surface finish while maintaining full compatibility with existing PET recycling streams.

However, Eastman’s European expansion faces hurdles. The proposed €900 million facility in Normandy has encountered delays due to insufficient offtake agreements. More critically, the U.S. Department of Energy’s recent withdrawal of $375 million funding for the Texas project has created financial uncertainties.

Industry analysts tell AsiaMB that while chemical recycling represents the next frontier for plastic sustainability, widespread adoption requires improved cost competitiveness and stronger policy support. “Eastman’s technology proves the technical viability,” notes Dr. Emily Chen, a circular economy specialist, “but the industry needs collaborative efforts across the value chain to achieve commercial scale.”

As regulatory pressure on plastic waste intensifies globally, Eastman’s solution offers brands a pathway to meet ambitious sustainability targets without compromising material performance. The coming years will prove decisive for this technology’s role in reshaping the plastics value chain.