April 3, 2025 – Electrical Wires and Cables: Unraveling the Causes and Prevention of Explosions and Fires

Electrical wires and cables, the lifelines of power and information transmission, play a critical role in our daily lives and industrial operations. However, the frequent occurrence of explosions and fires caused by wire and cable failures has resulted in significant losses to society. This article delves into the technical aspects of the major culprits behind these incidents and proposes corresponding preventive measures.

The reasons for explosions and fires in electrical wires and cables are manifold. Firstly, prolonged overload operation stands out as one of the primary offenders. When the current exceeds the carrying capacity of the wires and cables, the conductors overheat, accelerating the aging and even melting of the insulation layer, thereby posing a high risk of fire. This issue is exacerbated in older buildings or factories where high-power electrical appliances are added without upgrading the cable specifications.

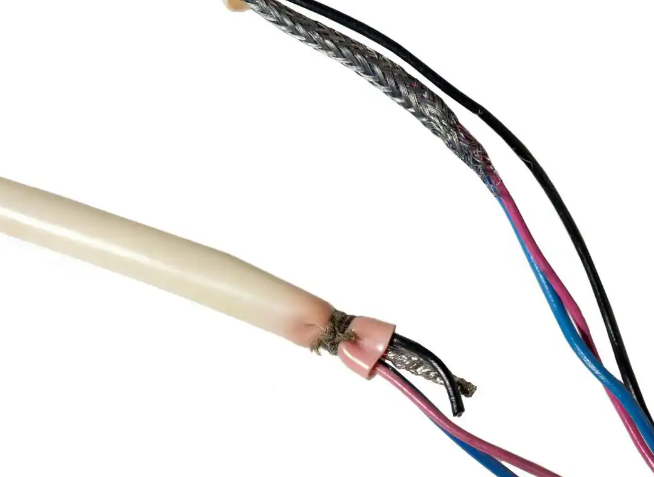

Secondly, short-circuit faults are another significant cause of wire and cable fires. Damage to the insulation, moisture ingress, or metal contact can all lead to phase-to-phase short circuits. The sudden surge in short-circuit current generates high-temperature arcs, rapidly igniting nearby combustible materials. In some cases, the short-circuit points may also produce molten metal splashes, fueling a larger-scale fire.

Furthermore, the aging or degradation of insulation materials cannot be ignored. Long-term exposure to high temperatures, ultraviolet radiation, chemical corrosion, and other environmental factors gradually impairs the performance of the insulation layer, causing it to harden, crack, or even peel off. Once the insulation fails, the exposed conductors are prone to discharge or leakage, creating potential fire hazards.

Additionally, poor contact and localized overheating are also contributors to wire and cable fires. Loose, oxidized, or corroded connection terminals increase contact resistance, generating localized high temperatures during operation. If not promptly detected and addressed, this can easily ignite adjacent combustible materials.

According to insights from the Color Masterbatch Industry Network, external factors also significantly impact the safe operation of electrical wires and cables. Mechanical damage, extreme ambient temperatures, and the accumulation of combustible materials are all potential triggers for wire and cable fires. For instance, construction activities may inadvertently sever cables, animals may gnaw on them, or heavy objects may crush them, leading to insulation damage. In high-temperature environments, the heat dissipation capacity of cables decreases, while low temperatures may brittle the insulation materials. The accumulation of oil, dust, or flammable debris in cable trenches can quickly escalate into a disaster once ignited.

To prevent electrical wire and cable fires, the following measures should be implemented: Firstly, scientific design and selection should be adopted, choosing appropriate cable specifications based on load requirements and allowing for some capacity margin. In flammable and explosive environments, flame-retardant, fire-resistant, or low-smoke zero-halogen cables should be used. Secondly, routine maintenance and monitoring should be strengthened, utilizing infrared thermal imaging cameras to periodically check the temperature of cable joints and conducting insulation resistance tests on older cables, with timely replacement of aging lines. Combustible materials in cable channels should be cleared to maintain good ventilation and heat dissipation. Thirdly, protective devices should be installed, including overload protection circuit breakers, leakage protectors, and arc fault circuit breakers in the distribution system. For critical lines, online monitoring systems can be added to real-time collect current and temperature data. Fourthly, construction and operation practices should be standardized, avoiding excessive bending of cables, employing reliable connection techniques at joints, and ensuring waterproof sealing. Unauthorized electrical connections and overloading of mobile sockets should be strictly prohibited.

In conclusion, the prevention of electrical wire and cable fires requires a multi-faceted approach, encompassing scientific selection, regular maintenance, intelligent monitoring, and standardized construction practices. By implementing these measures, we can effectively reduce the likelihood of accidents and ensure the safe operation of electrical wires and cables.