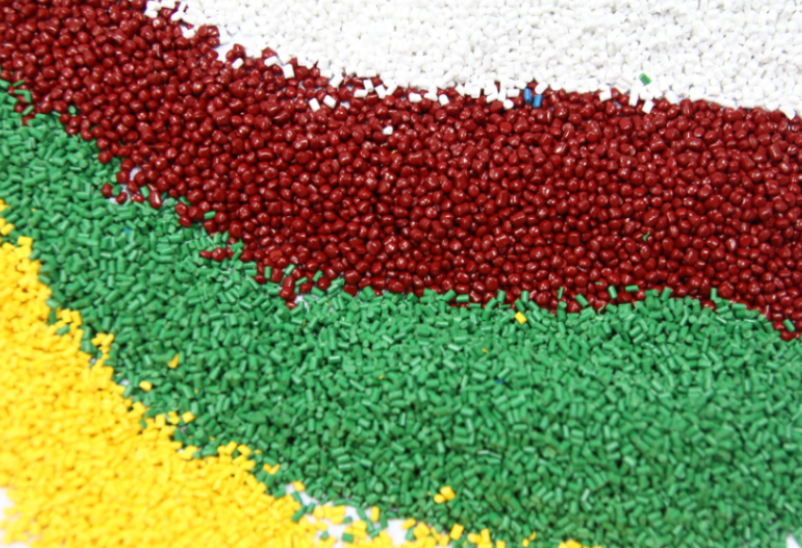

March 26, 2025 – Color Masterbatch, a novel specialized pigment for polymer materials, finds extensive application across various industrial sectors. Here are the primary directions in which it is utilized.

In the plastics industry, color masterbatch plays a pivotal role. On one hand, it serves as a versatile coloring agent for plastics such as polyethylene, polypropylene, polyvinyl chloride, and polystyrene. By incorporating diverse colors and proportions of masterbatch, manufacturers can produce a wide array of vibrant plastic products, including pipes, sheets, containers, films, and toys. Moreover, according to the Color Masterbatch Industry Network, certain masterbatches impart unique properties to plastics. For instance, the addition of masterbatch containing UV absorbers enhances the weather resistance of plastics, preventing degradation and fading due to UV exposure. Antistatic masterbatch, on the other hand, endows plastic surfaces with conductivity, reducing static buildup and mitigating issues like dust attraction and electric shocks.

The rubber industry also relies heavily on color masterbatch. It is employed for coloring rubber products like tires, seals, tubes, and sheets, exhibiting excellent dispersion in rubber to ensure uniform and vivid colors, meeting the aesthetic requirements of various applications. Specialized masterbatches can further improve rubber properties. For example, the incorporation of carbon black-containing masterbatch not only darkens rubber products but also boosts their strength, wear resistance, and conductivity. Certain metal oxide masterbatches enhance rubber’s heat resistance and aging performance.

In the fiber industry, color masterbatch is widely used. During the production of chemical fibers like polyester, nylon, and polypropylene, masterbatch is integral to fiber coloring. By blending masterbatch with polymer chips before spinning, manufacturers can produce colored fibers in an environmentally friendly and efficient manner, reducing wastewater discharge and energy consumption compared to traditional dyeing methods. Additionally, functional masterbatches impart specific properties to fibers. Antibacterial agent-containing masterbatch, for instance,granted fibers antimicrobial and odor-resistant qualities, making them ideal for medical and hygiene products and high-end apparel fabrics. Masterbatch with far-infrared emitting capabilities provides fibers with warmth retention and blood circulation promotion benefits, commonly used in functional textiles.

Lastly, the coatings industry benefits significantly from color masterbatch. It is utilized for color adjustment in coatings, where it is mixed, dispersed, and processed to achieve the desired hue. This method is more convenient and precise than traditional pigment mixing, reducing pigment dust and waste while improving efficiency and quality. Certain masterbatches also enhance coating properties. Rust-inhibiting pigment-containing masterbatch, for example, boosts the rust resistance of coatings, often used in metal anticorrosive coatings. Pearl effect masterbatch imparts a pearlescent gloss to coatings, enhancing their decorative appeal in high-end applications like automotive and furniture paints.