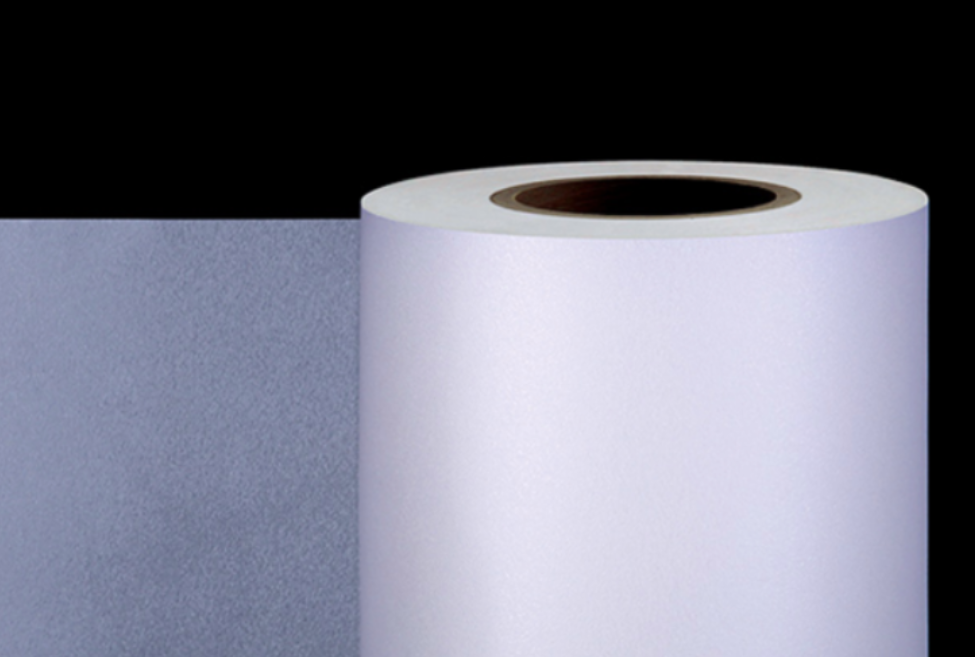

November 08, 2024 – As the photovoltaic industry continues to soar, PV encapsulant films, a vital material for the encapsulation of PV modules, are increasingly coming into the spotlight. These films serve as the “guardians” of solar cell modules, providing not only encapsulation and protection but also enhancing the modules’ photoelectric conversion efficiency and prolonging their lifespan. Based on different materials, PV encapsulant films are categorized into two major types: EVA films and POE films, which can be further subdivided into transparent EVA films, white-reinforced EVA films, POE films, and EPE films.

As the core encapsulation material for modules, PV encapsulant films maintain a close capacity ratio with the production of PV modules. Statistics indicate that each additional gigawatt (GW) of PV installed capacity corresponds to approximately 10-12 million square meters of PV encapsulant film demand. Consequently, in 2023, the global demand for PV encapsulant films is estimated to have reached 3.75-4.5 billion square meters. This upward trend in demand has persisted into the first half of 2024, highlighting the robust momentum of the PV industry.

In the current development of the global PV encapsulant film market, two notable characteristics stand out. Firstly, throughout the year, the shipment volume of PV encapsulant films is expected to continue growing. However, amidst the expanding market size, the industry is experiencing a phenomenon of increasing volume but decreasing prices, influenced by the decline in prices across the supply chain and fluctuations in raw material prices. Secondly, with continuous breakthroughs in various battery module technologies, the market is imposing higher and more diversified encapsulation requirements on PV encapsulant film products. This necessitates that film manufacturers possess not only strong technical capabilities but also the ability to continuously collaborate with downstream module manufacturers in technical iterations and product validations, thereby fostering a differentiated competitive landscape. According to AsiaMB’s sources, this capacity for technical iteration and product validation is becoming a crucial factor for film manufacturers to distinguish themselves in the market.