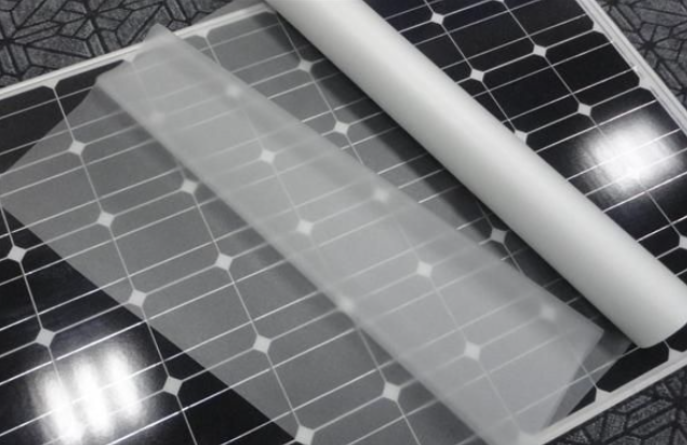

October 29, 2024 – Photovoltaic encapsulant films, serving as the crucial packaging material for solar cell modules, offer effective protection to solar cells and significantly enhance photoelectric conversion efficiency, thanks to their exceptional light transmittance and insulating properties. Currently, the mainstream photovoltaic encapsulant films on the market are primarily categorized into EVA (Ethylene Vinyl Acetate) films and POE (Polyolefin Elastomer) films.

EVA films, with EVA as their main component, achieve superior encapsulation performance through the addition of various additives such as crosslinking agents and thickeners. Their relatively affordable price has made them the preferred material for photovoltaic module encapsulation for a long time. However, EVA films also exhibit PID (Potential Induced Degradation) defects, which somewhat affect their service life.

In contrast, POE films are gradually making a name for themselves in the field of photovoltaic module encapsulation due to their high efficiency and reliability. According to AsiaMB’s understanding, POE films boast excellent moisture and ion barrier properties as well as outstanding aging resistance, making them particularly suitable for the encapsulation of bifacial modules. Although their processing performance is slightly inferior to EVA films, their long-term performance is more impressive.

The selection and use of additives are also crucial in the production process of photovoltaic encapsulant films. Crosslinking agents, as key components, significantly impact the crosslinking degree and performance of the films. Common crosslinking agents include thio-based and peroxide-based types, with peroxide-based agents further subdivided into alkyl peroxides, diacyl peroxides, and peroxide ketals. These crosslinking agents are typically used in amounts of around 1.5%, ensuring good crosslinking effects and stability of the films.

Furthermore, the addition of coupling agents, plasticizers, stabilizers, antioxidants, and protective agents further enhances the performance and service life of photovoltaic encapsulant films. For instance, coupling agents can enhance the polarity of EVA, improving the adhesion strength between the film and glass or TPT; plasticizers enhance the flexibility and ductility of the film, making its processing performance better; stabilizers and antioxidants prevent the decomposition and oxidation of the film during production, storage, and use, thereby extending its service life.

With the continuous development of the photovoltaic industry, the performance requirements for photovoltaic encapsulant films are also increasing. In the future, with the continuous emergence of new materials and advancements in additive technology, the performance of photovoltaic encapsulant films will be further enhanced, providing strong support for the sustained development of the photovoltaic industry.