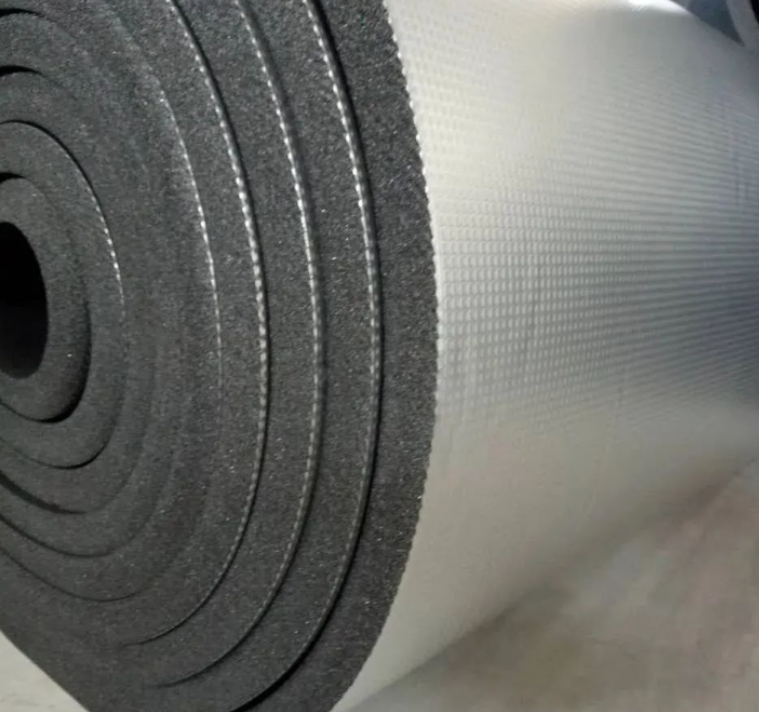

October 24, 2024 – Polyolefin foam, a lightweight and versatile material, has demonstrated extensive application potential in various sectors including packaging, construction, and automotive. This type of foam plastic, based on polyolefin, forms a unique pore structure through the expansion of blowing agents at high temperatures. This not only reduces material density but also significantly enhances its insulation and cushioning properties.

Among the various types of polyolefin foam, Polyethylene (PE) foam and Polypropylene (PP) foam are particularly noteworthy. The former has secured a niche in packaging, thermal insulation, and soundproofing materials due to its excellent flexibility and water resistance. The latter, with its high strength and rigidity, is preferred for automotive parts, building insulation, and industrial packaging. These foam materials, characterized by their lightweight, thermal insulation, cushioning, and chemical resistance, provide efficient and reliable solutions for diverse industries.

According to AsiaMB’s sources, a recent breakthrough has been made in enhancing the thermal insulation performance of polyolefin foam. Professor Ruiyan Zhang from Ningxia University, leading a team, has successfully developed COC foam with high expansion ratio and excellent thermal insulation performance, utilizing innovative blend micro-phase separation and in-situ fibrillation technologies based on cyclic olefin copolymer (COC). This achievement not only addresses the issues of low melt strength and poor thermal insulation performance of traditional linear polyolefin foams but also injects new vitality into the field of thermal insulation materials.

The remarkable thermal insulation performance of COC foam is primarily attributed to its unique cyclic olefin structure and micro-phase separation technology. The cyclic olefin structure effectively enhances thermal radiation shielding, reducing heat radiation transfer. Micro-phase separation, on the other hand, forms micro/nano-porous structures, further lowering the air heat transfer coefficient through the Knudsen effect. Experimental results demonstrate that this new COC foam significantly improves thermal insulation performance, showcasing its potential as a high-performance thermal insulation material.

Furthermore, COC excels in optical performance and is widely used in camera lenses, polarizers in LCD modules, and other applications. In the biopharmaceutical field, COC also exhibits unique advantages, becoming an essential material for prefilled syringes and vaccine packaging containers. With continuous technological advancements and expanding application areas, COC and its foam materials are expected to bring revolutionary changes and development opportunities to even more industries.