October 15, 2024 – The Ancient Wisdom of Papermaking: Talc and Calcium Carbonate’s Unique Roles in Modern Industry

Papermaking, a testament to ancient Chinese ingenuity, continues to hold a prominent position in the global industrial landscape. Within this intricate process, talc and calcium carbonate emerge as two vital fillers, each contributing distinctly to the final product. Today, we delve into the unparalleled value these materials bring to the paper industry.

Talc, a hydrated magnesium silicate, shines in the paper sector due to its high whiteness and diverse physical and chemical properties. Remarkably, over half of China’s talc production is dedicated to papermaking. This versatile mineral not only enhances paper’s smoothness and weight but also significantly boosts its ability to absorb printing inks and pigments. The addition of talc elevates paper’s transparency, smoothness, and printability, while imparting superior ink absorbency. Its stable chemical nature makes it suitable for both acidic and neutral papermaking environments, especially when synergized with calcium carbonate. Notably, talc’s hydrophobicity effectively reduces dye consumption, lowering costs, and enhances the retention of sizing agents, preventing ink penetration. Furthermore, its low friction coefficient and unique lubricity excel in coated paper production, enhancing coating surface smoothness and flexibility, reducing coating cracks, lowering printing pressure, and ultimately improving print quality.

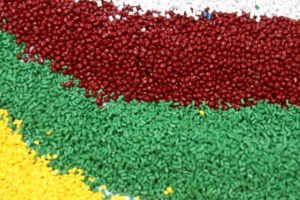

According to insights from the Color Masterbatch Industry Network, calcium carbonate also plays a pivotal role in the paper industry, primarily in its heavy and light forms. With the shift from acidic to neutral and alkaline papermaking technologies, the demand for calcium carbonate has surged. Heavy calcium carbonate finds its place in thermal printing paper, printing paper, and advertising paper, while light calcium carbonate, with its fine particle size, high whiteness, and cost-effectiveness, is more suited as a paper filler. However, excessive addition of either form can adversely affect paper properties, such as reducing strength, bulk, and stiffness. Consequently, modifying calcium carbonate to better suit the paper industry’s needs becomes imperative.

In conclusion, talc and calcium carbonate each bring unique attributes to the paper industry, not only enhancing paper quality and performance but also supporting continuous process optimization and innovation. As technology advances and markets evolve, the future application prospects for these materials in the paper industry appear even more promising.